Introduction to High Pressure Processing Process.

Food

processing is the transformation of raw animal or plant materials into products

that can be consumed to stabilize the food products by preventing or reducing

negative changes in quality. Without this food processing, the food cannot be

stored for a long time. Thus, this will be a problem for the food that need to

be transported for a long distance. Therefore, there are many food processing

technologies that can be explored and implemented in order to provide safety,

fresher-tasting and nutritive foods without using of heat or chemical

preservatives (E. Hogan, 2008) . One of the technologies

is by using high pressure processing (HPP).

High pressure processing (HPP)

is a non-thermal technique of food preservation that inactivates the harmful

pathogens and spoilage microorganisms by using pressure rather than heat to

induce a pasteurization effect. This pressure treatment can be used to both

liquid and solid foods with high moisture content (Giriprasad,

2015) .

Although it can kill the microorganisms, this pressure treatment does not break

the covalent bonds and has a minimal effect on food chemistry. Besides, the

treatment also can retain the food quality while avoiding the need for

excessive thermal processing or chemical preservatives. This treatment also

known as high hydro-static pressure (HHP) or ultra-high pressure (UHP)

processing (M.V. Muntean, 2016) .

Compared

to traditional thermal processing technology such as traditional thermal pasteurization,

HPP is performed at room temperature and thus reduces the energy consumption

that associated with heating and cooling process (M Sai

Srinivas, 2018) .

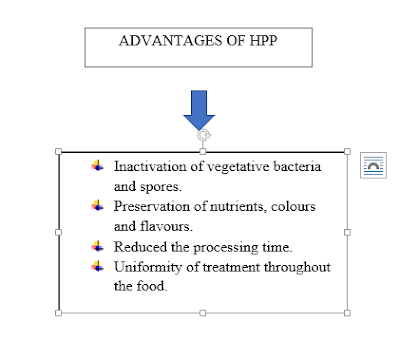

There are some advantages by using this high-pressure processing (HPP).

Figure 1: Denatured eggs by heat and pressure effect. (Source: M.V. Muntean, 2016)

Figure 1: Denatured eggs by heat and pressure effect. (Source: M.V. Muntean, 2016)

To

achieve the best pressure transmission, the ideal food for HPP has no gas

inclusions, no empty spaces in the package and a high content of moisture.

Vacuum packed products in flexible packages appear ideal for HPP, particularly

if the packaging could be compressed for about 15% with no structural damage

and if it were able to return to its original shape upon pressure release.

Currently, the flexible packs, jars, trays and bottles are used as HPP

packaging.

REFERENCES

E. Hogan, A. K. (2008). High

Pressure Processing of Foods:. An Overview.

Giriprasad, R. Y. (2015). HIGH

PRESSURE PROCESSING FOOD TECHNOLOGIES . International Journal of Science,

Environment and Technology, Vol. 4, No 1, 108 – 113.

M Sai Srinivas, B. M. (2018). High

Pressure Processing of Foods: A Review. The Andhra Agric. J 65,

467-476.

M.V. Muntean, O. M. (2016). High

pressure processing in food industry. Agriculture and agriculture science

procedia.

Comments

Post a Comment